PROFESSIONAL PIGMENT MANUFACTURER

Rubber pigment powder is engineered for elastomer coloration under extreme mechanical and environmental conditions. These organic formulations withstand vulcanization temperatures up to 180°C (ASTM D3182) while maintaining ≤0.7ΔE color stability. With 99% particle fineness below 3μm (ISO 13320), the powder ensures homogeneous dispersion in natural and synthetic rubbers without affecting tensile strength (±5% vs uncolored control per ASTM D412).

The colorants resist sulfur blooming and ozone degradation (≤0.5% surface bloom after 1,000 hours ASTM D1149). Produced at 700 metric tons monthly, our pigment delivers ≤1.8% batch variance for automotive, industrial, and medical rubber goods. Specialized dispersion aids prevent scorching during mixing, reducing Mooney viscosity variation to ±3 points (ASTM D1646).

Technical Advantages

50% lower compression set vs standard pigments

Resistance to oil/fuel extraction (ASTM D471)

0.02% weight loss at 150°C aging (ASTM D573)

Compatible with peroxide/EVE cure systems

Applications

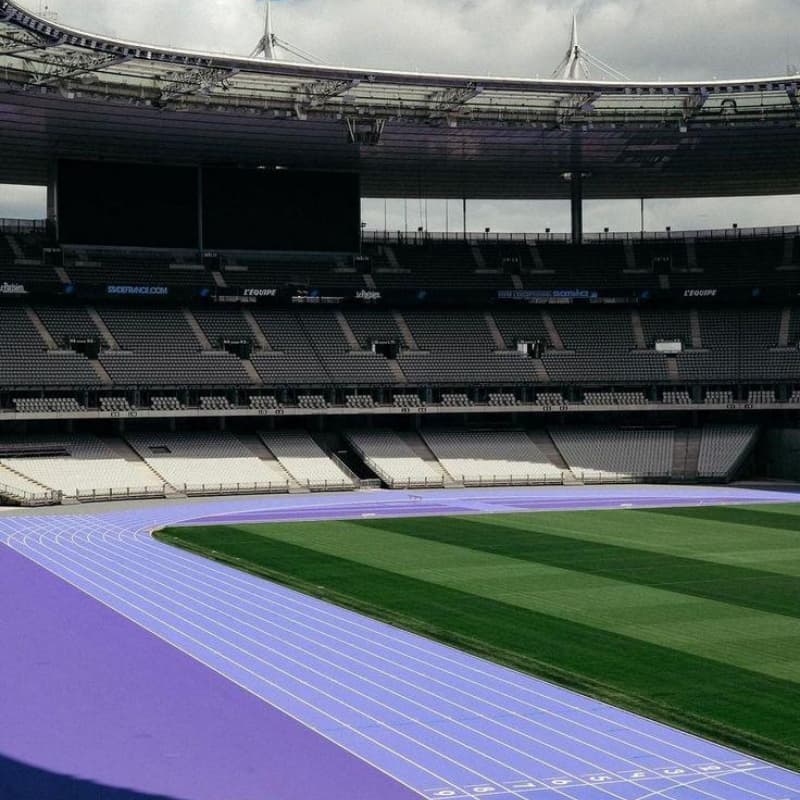

Automotive: Tire sidewall markings, engine seals, hoses.

Industrial: Vibration damping mounts, conveyor belts.

Medical: Sealing components, rubber stoppers.

Consumer Products: Rubber grips, elastic bands.

Certifications

REACH SVHC Compliance

ISO 9001:2015

FDA 21 CFR 177.2600

Project Cases

2016: European Tire Manufacturing

Supplied 30MT of ozone-resistant pigment for white sidewalls, maintaining ≤0.4ΔE after 50,000 km testing (ECE R30).

2021: North American Seals Project

Developed 22MT of low-compression-set pigment for engine mounts, achieving 12% longer service life (SAE J1131).

2023: Southeast Asian Medical Supply

Delivered 15MT of biocompatible pigment for syringe plungers, passing USP Class VI testing (ASTM D4169).

Copyright © 2024 Fineland Chem Co., Ltd /HangZhou FanCheng Chemical Co., Ltd.