PROFESSIONAL PIGMENT MANUFACTURER

|

Brand

|

Fineland Chem

|

|

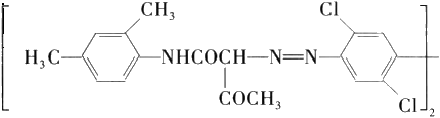

Color Index

|

Pigment Yellow 81 (PY81)

|

|

Color Index No

|

21127

|

|

CAS No

|

22094-93-5

|

|

EC No

|

224-776-0

|

|

Chemical Group

|

Mono Azo

|

| Chemical Formula | C₃₆H₃₂Cl₄N₆O₄ |

Pigment Yellow 81 (PY81) offers good lightfastness (6-7 grade), excellent heat and solvent resistance. It is ideal for solvent-based metal decoration inks, alkyd-melamine coatings, and polyolefins. It provides high durability in coatings and is suitable for PVC coloring, particularly in rigid PVC where it demonstrates a 7-grade lightfastness.

PY81 – DuraPlast®3181-1 ⬇️TDS

This is a greenish-yellow pigment with good transparency and clean shade, specially designed for plastic.

|

Test Item

|

Specification

|

|

Density (g/cm3 )

|

1.40-1.55

|

|

Specific Surface Area(m2/g)

|

20-30

|

|

Oil Absorption(g/100g)

|

35-45

|

|

PH Value

|

6.5-7.5

|

|

Bulk Density (lb/gal)

|

11.0-12.5

|

|

Total impurities(ppm)

|

≤600

|

| Heat Resistance (℃) | 240 | Alkali Resistance (1-5) | 5 |

| Light Resistance (Full Shade, 1-8) | 7 | Migration Resistance(1-5) | 5 |

| Light (Reduced tinting, 1-8) | 6 | Ethyl Acetate (1-5) | 4 |

| Weather Resistance (1-5) | 5 | Ethanol (1-5) | 5 |

| Acid Resistance (1-5) | 5 | MEK (1-5) | 4 |

Printing Ink: Discover high-performance ink pigments for various printing technologies including water-based, solvent-based, offset, inkjet, UV curing, and decorative applications. More Details

Paint and Coating: Explore a wide range of coating pigments tailored for paints, oils, automotive finishes, industrial applications, concrete, cement, and ceramics. More Details

Plastic and Masterbatch: Browse a comprehensive selection of plastic pigments designed for PE, PVC, EVA, rubber, and a variety of engineering plastics. More Details

Special Use: Find specialized pigments offering unique effects and functionalities for textiles, resins, glazes, metallic finishes, fluorescence, and anti-corrosion needs. More Details

Excellent Lightfastness: With a rating of 6-7, Pigment Yellow 81 offers outstanding color stability, ensuring long-lasting brightness in both coatings and inks.

Superior Heat Resistance: Can withstand temperatures up to 260°C for 5 minutes, making it suitable for high-temperature applications like PVC and polyolefins.

Strong Solvent Resistance: Demonstrates excellent durability and stability in solvent-based systems, ideal for metal decoration inks and industrial coatings.

High Opacity and Coverage: Provides strong hiding power, allowing vibrant and consistent coloring, even at low pigment concentrations.

| C.I. Pigment Yellow 81 | Permanent Yellow H 10G | Permanent Yellow H10G | Symuler Fast Yellow 4074 |

| C.I. 21127 | PV Yellow H108 | PV Yellow H10G 01 | Symuler Fast Yellow F10G |

| Benzidine Yellow 10G | 6128 Benzidine Yellow 10G | Sanyo Pigment Yellow 8104 | Yellow PEC-303 |

| Plasco Yellow 81 | Basoflex Yellow 099 | Suimei Yellow F10G | Yellow Vm-303 |

| Lithol Fast Yellow 0991K | Novoperm Yellow H10G 01 |

| 2,2′-[(2,2′,5,5′-Tetrachloro[1,1′-biphenyl]-4,4′-diyl)bis(azo)]bis[N-(2,4-dimethylphenyl)-3-oxobutyramide] |

| Butanamide, 2,2-(2,2,5,5-tetrachloro1,1-biphenyl-4,4′-diyl)bis(azo)bisN-(2,4-dimethylphenyl)-3-oxo- |

| 2,2′-[(2,2′,5,5′-Tetrachloro[1,1′-biphenyl]-4,4′-diyl)bis(azo)]bis[N-(2,4-dimethylphenyl)-3-oxo-butanamide] |

| 2,2′-[(2,2′,5,5′-Tetrachloro[1,1′-biphenyl]-4,4′-diyl)bis(2,1-diazenediyl)]bis[N-(2,4-dimethylphenyl)-3-oxobutamide] |

Copyright © 2024 Fineland Chem Co., Ltd /HangZhou FanCheng Chemical Co., Ltd.