PROFESSIONAL PIGMENT MANUFACTURER

|

Brand

|

Fineland Chem

|

|

Color Index

|

Pigment Yellow 17

|

|

Color Index No

|

21105

|

|

CAS No

|

4531-49-1

|

|

EC No

|

224-867-1

|

|

Chemical Group

|

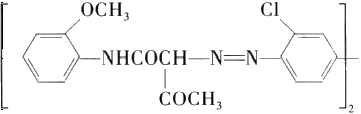

Disazo

|

| Chemical Formula | C₃₄H₃₀Cl₂N₆O₆ |

This pigment finds wide use in packaging printing (nitrocellulose and polyamide inks, EVA/PE copolymer binders), in polyolefin coloration for high-temperature extrusion, and in PVC film and masterbatch applications for cable insulation. Its excellent dispersibility in vinyl acetate systems and robust thermal resistance make it suitable for coatings, printing and textile pulp coloration too.

PY17 – DuraPlast®3117-2 ⬇️TDS

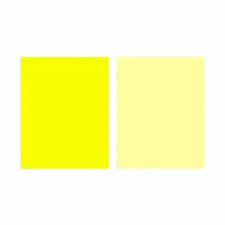

This is a greenish-yellow pigment with high transparency and strong color strength, specially designed for plastic applications requiring bright and clean shades

|

Test Item

|

Specification

|

|

Density (g/cm3 )

|

1.30-1.55

|

|

Specific Surface Area(m2/g)

|

54-65

|

|

Oil Absorption(g/100g)

|

40-45

|

|

PH Value

|

6.0-7.5

|

|

Bulk Density (lb/gal)

|

10.8-12.9

|

|

Total impurities(ppm)

|

≤600

|

| Heat Resistance (℃) | 220 | Alkali Resistance (1-5) | 4 |

| Light Resistance (Full Shade, 1-8) | 6-7 | Migration Resistance(1-5) | 3-4 |

| Light (Reduced tinting, 1-8) | 5-6 | Ethyl Acetate (1-5) | 4 |

| Weather Resistance (1-5) | 3-4 | Ethanol (1-5) | 4 |

| Acid Resistance (1-5) | 4 | MEK (1-5) | 4 |

Printing Ink: Discover high-performance ink pigments for various printing technologies including water-based, solvent-based, offset, inkjet, UV curing, and decorative applications. More Details

Paint and Coating: Explore a wide range of coating pigments tailored for paints, oils, automotive finishes, industrial applications, concrete, cement, and ceramics. More Details

Plastic and Masterbatch: Browse a comprehensive selection of plastic pigments designed for PE, PVC, EVA, rubber, and a variety of engineering plastics. More Details

Special Use: Find specialized pigments offering unique effects and functionalities for textiles, resins, glazes, metallic finishes, fluorescence, and anti-corrosion needs. More Details

Bright Greenish-Yellow Shade:

Provides a vivid, clean hue with excellent brightness and visual appeal.

Good Transparency and High Tinting Strength:

Ensures strong color development and vibrant appearance even at low pigment loadings.

Excellent Dispersibility and Processing Stability:

Performs well in various resin systems such as nitrocellulose, polyamide, and EVA copolymers.

Good Heat Resistance (220–240 °C):

Suitable for high-temperature plastic processing and extrusion applications.

Reliable Lightfastness (Grade 4–5):

Maintains color stability under light exposure for durable performance.

Good PVC Compatibility and Electrical Insulation:

Ideal for use in PVC cable sheathing and film coloration.

Cost-Effective Performance:

Combines strong color strength and durability with excellent economic value.

| Pigment Yellow 17 | Benzidine Yellow GG | Organic Pigment Yellow 17 | Micronyl Yellow 2GP-AQ |

| C.I. 21105 | Pigment Yellow GG | Alkyd Flush(A75-1468) | Lionol Yellow FGN |

| C.I. Pigment Yellow 17 | Fast Yellow 2G | Diarylide Yellow AAOA | Pigmatex Yellow 3G |

| CAS 4531-49-1 | Permanent Yellow 2G | Flexobrite Yellow AD17 | Sunbrite Yellow 17(475~0586) |

| P.Y. 17 | Plasco Yellow 17 | Foscolor Yellow 17 | Symuler Yellow 8GTF |

| Permanent Yellow GG | Permanent Yellow GG 1124 | Hostaprint Yellow GG31 |

Copyright © 2024 Fineland Chem Co., Ltd /HangZhou FanCheng Chemical Co., Ltd.