PROFESSIONAL PIGMENT MANUFACTURER

|

Brand

|

Fineland Chem

|

|

Color Index

|

Pigment Yellow 34

|

|

Color Index No

|

13980

|

|

CAS No

|

1344 – 37 – 2

|

|

EC No

|

250 – 830 – 4

|

|

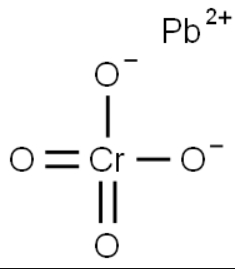

Chemical Group

|

Chrome series

|

| Chemical Formula | PbCrO₄ + PbSO₄ |

Pigment Yellow 34, bright and opaque yellow color. High tinting strength, excellent light fastness, and resistance to high temperatures, making it suitable for a variety of applications.

PY34 – DuraPaint®6134L ⬇️TDS

It excels in paint and coating applications with its high opacity, vibrant yellow hue, and resistance to 220°C, ensuring durable colorfastness in both indoor/outdoor coatings and compatibility with various binders for long-lasting performance.

PY34 – DuraPaint®6134M ⬇️TDS

It excels in paint and coating applications with its high opacity, vibrant yellow hue, and resistance to 220°C, ensuring durable colorfastness in both indoor/outdoor coatings and compatibility with various binders for long-lasting performance.

PY34 – DuraPlast®C3134M ⬇️TDS

This grade offers a distinct advantage in plastic applications with its ability to withstand 220°C, ensuring no color degradation or thermal breakdown during extrusion, injection molding, or thermoforming processes while maintaining vibrant yellow hue and pigment stability in polyolefins, PVC, and other thermoplastics.

|

Test Item

|

Specification

|

|

Density (g/cm3 )

|

5.4

|

|

Specific Surface Area(m2/g)

|

9

|

|

Oil Absorption(g/100g)

|

20-25

|

|

PH Value

|

6-8

|

|

Bulk Density (lb/gal)

|

100

|

|

Total impurities(ppm)

|

≤600

|

| Heat Resistance (℃) | 220 | Alkali Resistance (1-5) | 3 |

| Light Resistance (Full Shade, 1-8) | 5-6 | Migration Resistance(1-5) | 4 |

| Light (Reduced tinting, 1-8) | 5 | Ethyl Acetate (1-5) | 5 |

| Weather Resistance (1-5) | 3 | Ethanol (1-5) | 5 |

| Acid Resistance (1-5) | 5 | MEK (1-5) | 5 |

Some of the key applications of lead chrome yellow pigment include industrial coatings, architectural coatings, plastics and rubber, printing inks, ceramics and glass, etc.

It’s important to note that due to the health and environmental risks associated with lead-based pigments, the use of these pigments has significantly decreased in recent years. Many countries have implemented regulations and restrictions on the use of lead-containing pigments, and as a result, manufacturers have sought alternatives to ensure safety and compliance.

Printing Ink: Discover high-performance ink pigments for various printing technologies including water-based, solvent-based, offset, inkjet, UV curing, and decorative applications. More Details

Paint and Coating: Explore a wide range of coating pigments tailored for paints, oils, automotive finishes, industrial applications, concrete, cement, and ceramics. More Details

Plastic: Browse a comprehensive selection of plastic pigments designed for PE, PVC, EVA, rubber, and a variety of engineering plastics. More Details

Special Applications: Find specialized pigments offering unique effects and functionalities for textiles, resins, glazes, metallic finishes, fluorescence, and anti-corrosion needs. More Details

● 25KG Kraft bag,1000KG Carton Box.

● Lead Time: Normally around 15 days after signed contract.

Copyright © 2024 Fineland Chem Co., Ltd /HangZhou FanCheng Chemical Co., Ltd.