PROFESSIONAL PIGMENT MANUFACTURER

It is primarily utilized for grinding pigments into a finely powdered or pasted form, enhancing dispersion and facilitating application within various industries, including coatings, inks, plastic, and more.

It is a commonly utilized tool for the blending and homogenization of pigments, primarily employed for the efficient mixing and dispersion of pigments, fillers, and additional additives.

Usually test the pigment basic performance which applied in plastic and rubber.

Usually test the pigment property which applied in water based system like printing ink or paint.

It is standard procedure to test the pigment characteristics used in solvent-based coatings by subjecting them to prolonged exposure in a baking oven.

It is essential in supporting the production of diazo pigments by creating a controlled and effective setting for the diazo reaction. This facilitates the creation of premium-quality pigments with the desired color properties and stability.

It is engineered to accommodate a diverse array of pigment types, including both organic and inorganic options. This system enables meticulous regulation of the blending procedure, facilitating the attainment of desired color intensity, shade, and uniformity.

This process enhances the quality and purity of pigments by efficiently eliminating unwanted particles and impurities. It can result in uniform and premium pigment powders or pastes, suitable for further refinement and utilization across diverse applications.

Ensuring the thorough drying of pigments is essential for eliminating moisture and solvents, preparing them for subsequent processing or packaging. This meticulous process safeguards the stability, color uniformity, and longevity of pigments, thereby optimizing their utility across diverse applications.

It’s an air pollution control device and dust collector that removes particulates or gas released from commercial processes out of the air. Functioning baghouses typically have a particulate collection efficiency of 99% or better, even when particle size is very small.

The process of pulverizing or grinding pigments into a fine powder is essential for improving their dispersion in various industries, including paint, ink, plastic, and other color-related industries. This method not only enhances the color strength and consistency of pigments but also enhances their overall quality.

It is essential in supporting the production of diazo pigments by creating a controlled and effective setting for the diazo reaction. This facilitates the creation of premium-quality pigments with the desired color properties and stability.

It is engineered to accommodate a diverse array of pigment types, including both organic and inorganic options. This system enables meticulous regulation of the blending procedure, facilitating the attainment of desired color intensity, shade, and uniformity.

This process enhances the quality and purity of pigments by efficiently eliminating unwanted particles and impurities. It can result in uniform and premium pigment powders or pastes, suitable for further refinement and utilization across diverse applications.

Ensuring the thorough drying of pigments is essential for eliminating moisture and solvents, preparing them for subsequent processing or packaging. This meticulous process safeguards the stability, color uniformity, and longevity of pigments, thereby optimizing their utility across diverse applications.

It’s an air pollution control device and dust collector that removes particulates or gas released from commercial processes out of the air. Functioning baghouses typically have a particulate collection efficiency of 99% or better, even when particle size is very small.

The process of pulverizing or grinding pigments into a fine powder is essential for improving their dispersion in various industries, including paint, ink, plastic, and other color-related industries. This method not only enhances the color strength and consistency of pigments but also enhances their overall quality.

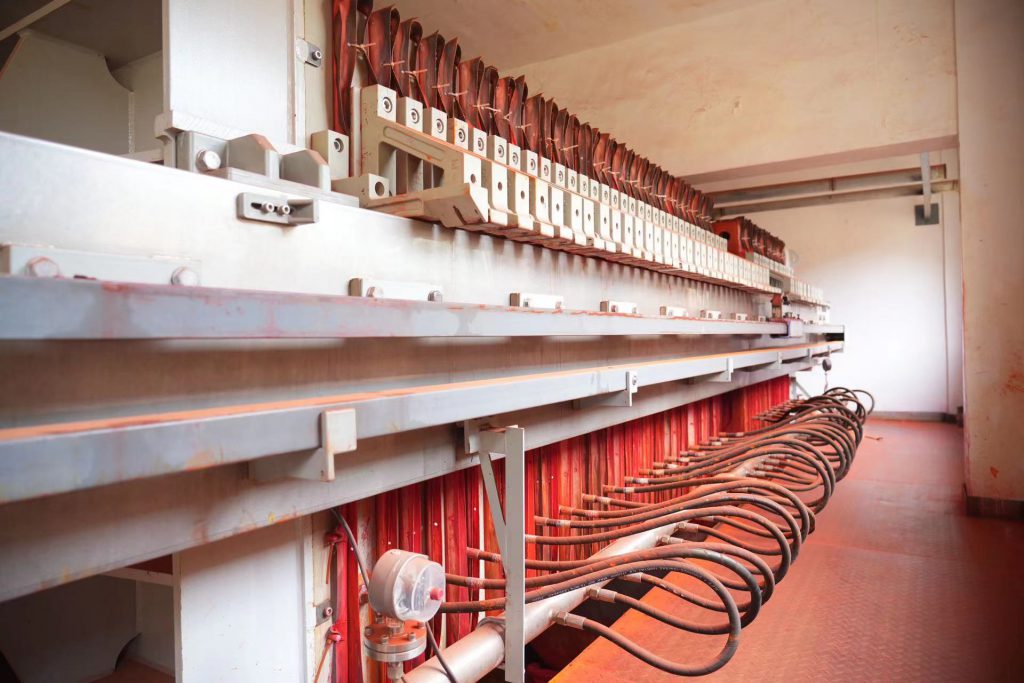

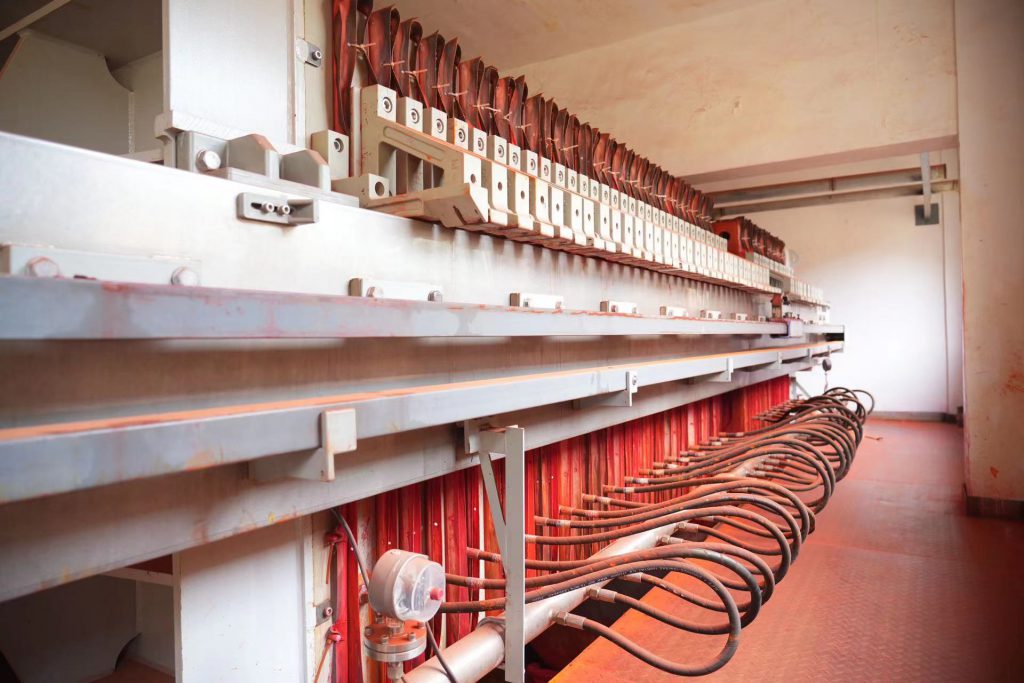

The automated assembly line can greatly improve the work efficiency of workers, reduce the error rate, increase the output.4 production lines can be working at the same time. The daily output is up to 20 mts.

At Fineland Chem, we prioritize the maintenance of high-quality standards across all our products and services. Our dedication to continuous improvement in our manufacturing process and product quality ensures optimal performance and aims to achieve a “Zero Defect” outcome in all our daily operations.

Our goal is to deliver satisfactory and effective customer support, timely delivery, and appropriate features at competitive prices.

Yes, no problem. We are happy to be helpful to our client and we are in the position to supply related services such as logistic , quality control, factory inspection .....etc. We can combine the shipment with your other products.

The lead time for our organic pigments can vary depending on the specific type of pigment and the quantity you require. We can provide you with more accurate lead time information once we know the specific pigment you are interested in and the quantity you need.

Generally, for standard organic pigments that are readily available in our inventory, the lead time can be relatively short, ranging from a few days to a couple of weeks. However, if you require a large quantity or a custom-made pigment, the lead time may be longer to ensure the production and quality control processes are adequately completed.

Details are like this: usually we have regular product stock (2-3mt) in our warehouse near Shanghai. Normally can book shipment within order confirmed 14days. When special product or big quantity we will inform in advance.

Welcome to inquire from us. If you have any specific concerns or additional questions about our product, service procedures, please don't hesitate to ask! We are open-minded to discuss together.

Our company offers flexible payment terms to accommodate the needs of our customers. The specific payment terms may vary based on factors such as the order volume, the nature of the business relationship, and other mutually agreed-upon terms. However, some common payment terms we offer include:

At present Fineland only have one factory in China, not develop agent overseas so far. You can directly buy from us, our air and sea transportation also convenient. If you rather buy from local, we can introduce our distributor customers to you.

Yes, we have customized service, after each other's fully communication, our technical person will adjust the formal and try to match your requirement.

Yes, no problem. We are happy to be helpful to our client and we are in the position to supply related services such as logistic , quality control, factory inspection .....etc. We can combine the shipment with your other products.

The lead time for our organic pigments can vary depending on the specific type of pigment and the quantity you require. We can provide you with more accurate lead time information once we know the specific pigment you are interested in and the quantity you need.

Generally, for standard organic pigments that are readily available in our inventory, the lead time can be relatively short, ranging from a few days to a couple of weeks. However, if you require a large quantity or a custom-made pigment, the lead time may be longer to ensure the production and quality control processes are adequately completed.

Details are like this: usually we have regular product stock (2-3mt) in our warehouse near Shanghai. Normally can book shipment within order confirmed 14days. When special product or big quantity we will inform in advance.

Welcome to inquire from us. If you have any specific concerns or additional questions about our product, service procedures, please don't hesitate to ask! We are open-minded to discuss together.

Our company offers flexible payment terms to accommodate the needs of our customers. The specific payment terms may vary based on factors such as the order volume, the nature of the business relationship, and other mutually agreed-upon terms. However, some common payment terms we offer include:

At present Fineland only have one factory in China, not develop agent overseas so far. You can directly buy from us, our air and sea transportation also convenient. If you rather buy from local, we can introduce our distributor customers to you.

Yes, we have customized service, after each other's fully communication, our technical person will adjust the formal and try to match your requirement.

Since 2008, Fineland Chem has been a leading manufacturer of organic pigments, recognized for developing innovative color solutions. Our extensive product range includes over 100 types of pigments, from azo to phthalocyanine pigments. With an annual production capacity exceeding 10,000 tons, we ensure a stable supply of high-quality organic pigments.

Copyright © 2024 Fineland Chem Co., Ltd /HangZhou FanCheng Chemical Co., Ltd.