PROFESSIONAL PIGMENT MANUFACTURER

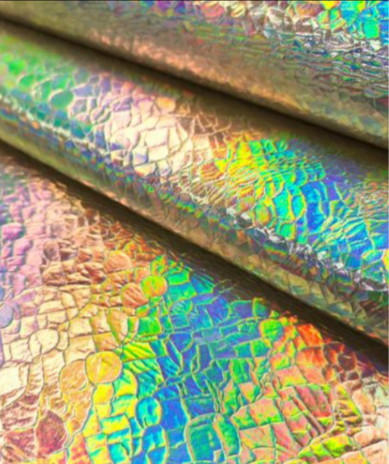

Effect pigment powder creates iridescent, chameleon, and holographic finishes through layered oxide coatings on mica substrates. These organic formulations achieve ΔE 15 color travel (ASTM D5767) with 99% platelet alignment in coatings. The powder withstands 180°C curing (ASTM D2486) and maintains 95% reflectivity after 3,000 hours QUV-B (ISO 4892).

Engineered for automotive and aerospace applications, our pigments reduce application steps by 40% through single-layer effects. Produced at 700MT monthly, batches show ≤1.5% variance in flake thickness (ISO 13320), critical for OEM color matching.

Technical Advantages

150°-75° bidirectional reflectance

≤0.2% flake fracture during spraying

Compatible with electrostatic application

REACH and ELV compliant

Applications

Luxury automotive exteriors

Aircraft interior decorative panels

Premium appliance finishes

Certifications

GMPA 6-20

ISO 9001:2015

REACH Annex XVII

Project Cases

2019: European Supercar Project

Supplied 8MT of chameleon pigment, achieving 120° color shift (SAE J2527).

2022: US Aerospace Interior

Developed 12MT of lightweight effect pigment, reducing cabin coatings by 30% weight.

2024: Southeast Asian Electronics

Delivered 15MT of conductive effect pigment for EMI shielding (IEC 61000-4-21).

Copyright © 2024 Fineland Chem Co., Ltd /HangZhou FanCheng Chemical Co., Ltd.