Introduction

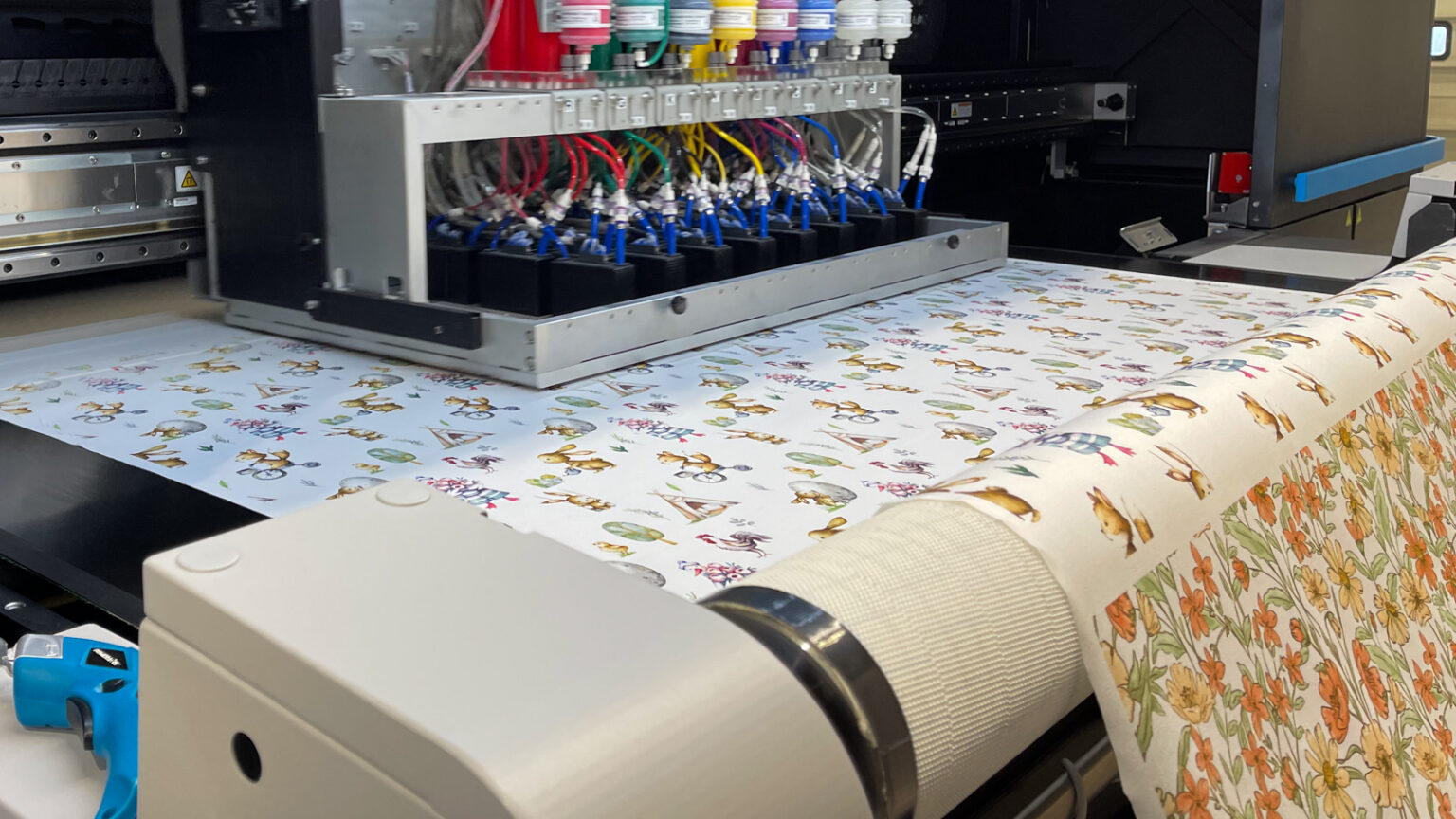

Screen printing is an immensely popular technique used in various industries, from textiles to graphics and packaging. The key to achieving vibrant, long-lasting prints lies in the pigments used during the process. But with so many types of screen printing pigments available, how do you know which one is right for your project? In this blog, we’ll explore the crucial factors to consider when choosing the right screen printing pigment, helping you achieve the best results every time.

What Are Screen Printing Pigments?

Screen printing pigments are colorants that give the ink its color, and they play a vital role in the overall quality of the print. Unlike dyes, which dissolve in liquids, pigments are typically solid particles suspended in a medium. These particles provide opacity, vividness, and durability, making them essential for high-quality screen printing.

There are various types of screen printing pigments, each with its own characteristics and applications. Understanding the differences will help you select the right one for your printing needs.

Factors to Consider When Choosing Screen Printing Pigments

1. Color Intensity and Vibrancy

The first thing you’ll notice when selecting a screen printing pigment is the color intensity. Pigments come in a range of hues, from vibrant, eye-catching shades to more muted tones. The right pigment should match your design requirements and stand out in the final product.

For instance, if you’re printing on a light-colored fabric, you can use less pigmented inks. However, for darker substrates, a higher concentration of pigment is necessary to achieve rich, visible prints.

2. Opacity

Opacity refers to how much light can pass through the pigment. This is an essential factor when printing on different backgrounds. If you’re printing on a dark fabric or surface, you’ll need highly opaque pigments to ensure that the design appears clear and bold. Transparent pigments work better on light-colored materials or when you need to create multi-layered designs.

3. Durability and Resistance

A great screen print isn’t just about appearance—it’s also about how well it stands up to wear and tear. The durability of screen printing pigments depends on their ability to resist fading, cracking, and washing out. Choose pigments with high resistance to UV rays, abrasion, and environmental factors if your prints will be exposed to harsh conditions.

4. Type of Surface and Application

Different materials require different pigments. For instance, textiles, ceramics, plastics, and metals each have unique properties that affect how pigments interact with the surface. You’ll need to choose pigments that are specifically designed for the type of material you are printing on.

-

Textiles: Water-based pigments work well for fabrics, especially in apparel screen printing.

-

Plastics and metals: Solvent-based or UV-cured pigments may be more suitable for these materials.

-

Paper and cardboard: Often, a simple water-based pigment is enough for paper products.

5. Eco-Friendliness

In today’s environmentally-conscious world, sustainability is becoming an increasingly important factor in the decision-making process. Eco-friendly pigments made from natural materials or those with lower environmental impact are becoming more accessible. If your brand values sustainability, opting for non-toxic, biodegradable pigments will help align your projects with eco-friendly standards.

Types of Screen Printing Pigments

1. Water-Based Pigments

Water-based pigments are widely used for textile printing because of their soft finish and eco-friendly nature. They’re less likely to irritate the skin, which makes them ideal for clothing and apparel. While water-based pigments tend to be more opaque, they’re often used with additives to improve their durability and performance.

2. Plastisol Pigments

Plastisol pigments are popular for printing on textiles, especially for T-shirts. They offer excellent opacity and durability. Plastisol ink is thicker and requires curing at higher temperatures, making it suitable for designs that need to last through multiple washes.

3. UV Pigments

UV pigments cure with ultraviolet light, creating a fast-drying, durable print. These pigments offer excellent resistance to fading, making them ideal for outdoor applications or products exposed to sunlight. UV inks can be a bit more expensive but offer exceptional durability.

4. Solvent-Based Pigments

Solvent-based pigments are commonly used for printing on non-porous materials such as plastics, metals, and ceramics. They tend to dry quickly and form a strong bond with the material, ensuring long-lasting prints. However, they can be harmful to the environment, so proper ventilation and protective gear are necessary when using them.

5. Discharge Pigments

Discharge pigments are special in that they remove color from fabric rather than adding color to it. These pigments are often used in vintage-style designs on dark fabrics, as they bleach the dye in the fabric and replace it with a new color. Discharge printing offers unique, soft prints but requires specific conditions to work well.

How to Choose the Right Pigment for Your Project

When selecting a pigment for your project, consider the following tips:

1. Match the Pigment to the Substrate

The type of material you’re printing on will determine the best pigment to use. Always choose pigments that are designed for your substrate to ensure optimal performance and durability.

2. Consider Your Design’s Complexity

Intricate designs with multiple colors may require different types of pigments, so be sure to choose pigments that blend well together and won’t bleed or mix undesirably.

3. Think About Production Volume

For large-scale production runs, you might opt for more durable pigments like plastisol or UV-based inks to reduce the need for touch-ups or reprints.

4. Eco-Friendly Choices

If sustainability is important to you, look for water-based or natural pigments to reduce your environmental footprint.

Conclusion

Choosing the right screen printing pigment for your project is crucial for achieving high-quality prints that stand the test of time. Whether you’re working on textiles, ceramics, or packaging, understanding the different types of pigments and their unique characteristics will help you make an informed decision. By considering color intensity, opacity, durability, and material compatibility, you can ensure that your prints are vibrant, long-lasting, and aligned with your project’s needs.