Introduction

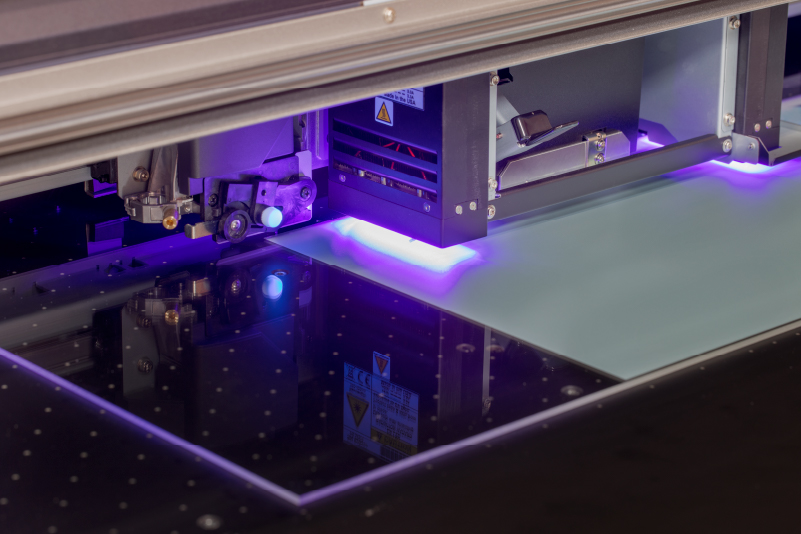

In an era when fast, high-quality printing is essential across industries, UV curing inkjet inks have emerged as a revolutionary technology. By instantly solidifying ink with ultraviolet (UV) light, these inks achieve stunning print quality, versatility, and efficiency. This guide explains how they work, why they’re increasingly popular, and where they are being used today.

1. How UV Curing Inkjet Inks Work

UV curing relies on a photochemical reaction: ink formulations contain monomers, oligomers, photoinitiators, pigments, and additives. When UV light strikes the ink, photoinitiators generate free radicals that trigger polymerization, turning liquid ink into a solid film in seconds.

Unlike solvent- or water-based inks that depend on evaporation, UV inks fully cure through chemical transformation. This provides near 100% ink utilization—no solvent is lost or absorbed.

2. Core Components of UV Inkjet Inks

-

Monomers & Oligomers: These reactive resins shape the ink’s viscosity, flexibility, hardness, and adhesion; low-viscosity mono- or di-functional monomers help achieve optimal jetting SpecialChem.

-

Photoinitiators: Crucial for initiating fast curing, though they may compete with oxygen in the air—a challenge solved by optimizing photoinitiator concentration.

-

Pigments & Additives: Provide vibrant colors, stability, and improved substrate bonding.

3. What Makes UV Inks Better?

-

Instant curing: Once exposed to UV, prints are fully dry and ready for handling—no elevators or curing tunnels needed.

-

Superior print quality: High gloss, sharp detail, intense color, and no dot gain since the ink sits atop the substrate.

-

Environmental benefits: They contain little to no volatile organic compounds (VOCs), making them greener and regulatory-friendly.

-

Broad substrate compatibility: Effective on plastics, metals, glass, wood, ceramics, foam board, and more—no pre-treatment required.

-

Enhanced durability: Print films are scratch, abrasion, chemical-, UV-, and weather-resistant.

4. Limitations to Consider

-

Higher ink cost: Specialized monomers and photoinitiators make UV inks more expensive.

-

Curing challenges: Thick ink layers or uneven exposure may lead to incomplete curing or clogging in printheads.

-

Oxygen inhibition: Oxygen can hinder curing, countered by adjusting photoinitiator amounts.

5. UV Curing Technologies

-

Mercury vapor lamps: Traditional high-intensity lamps, now being replaced due to environmental concerns.

-

UV-LED curing systems: Offer lower energy consumption, longer lifespan, no mercury, reduced heat, and scalable retrofits.

-

Dual‑cure systems: Compatible with both conventional UV and LED lamps; popular in hybrid printing setups.

6. Where UV Inkjet Inks Are Used

-

Signage & Displays: Ideal for both indoor and outdoor use due to durability and print quality.

-

Label & Packaging: Enables variable data printing, food-safe packaging, flexible cartons, corrugated boxes, and promotional packaging.

-

Direct‑to‑shape & 3D printing: Allows printing on unique shapes and even for stereolithography & DTF applications.

-

Electronics: Printing of conductive inks, circuit boards, overlays, and membrane switches.

-

Medical & Industrial: Used for durable labels on medical devices, equipment, and protective coatings.

7. Emerging Trends & Future Outlook

-

Market growth: Valued at around $1.2B in 2023, with a projected CAGR of ~7.5%, aiming for $2B by 2032.

-

UV-LED dominance: Rapid shift toward energy-efficient, sustainable LED curing; dual-cure inks are increasingly prevalent.

-

Eco‑innovations: Focus on low-migration inks, recyclable packaging, and green monomer sources.

-

Smart inks & printing: Integration of sensors for freshness, authentication, and interactive packaging.

-

Color expansion: Beyond standard CMYK, new inks support extended gamuts (orange, green, gray) to meet advanced printing demands.

Conclusion

UV curing inkjet inks represent a seismic shift in digital printing—offering instant drying, exceptional print quality, versatility, and sustainability. While they entail higher cost and technical nuances, the benefits far outweigh the challenges. With innovations like LED curing, dual-curable formulations, and eco-focused materials, UV printing is set to dominate across packaging, signage, electronics, and high-tech industrial sectors.

To explore more about UV curing inkjet inks, check out this detailed page: UV Curing Inkjet Inks.