PROFESSIONAL PIGMENT MANUFACTURER

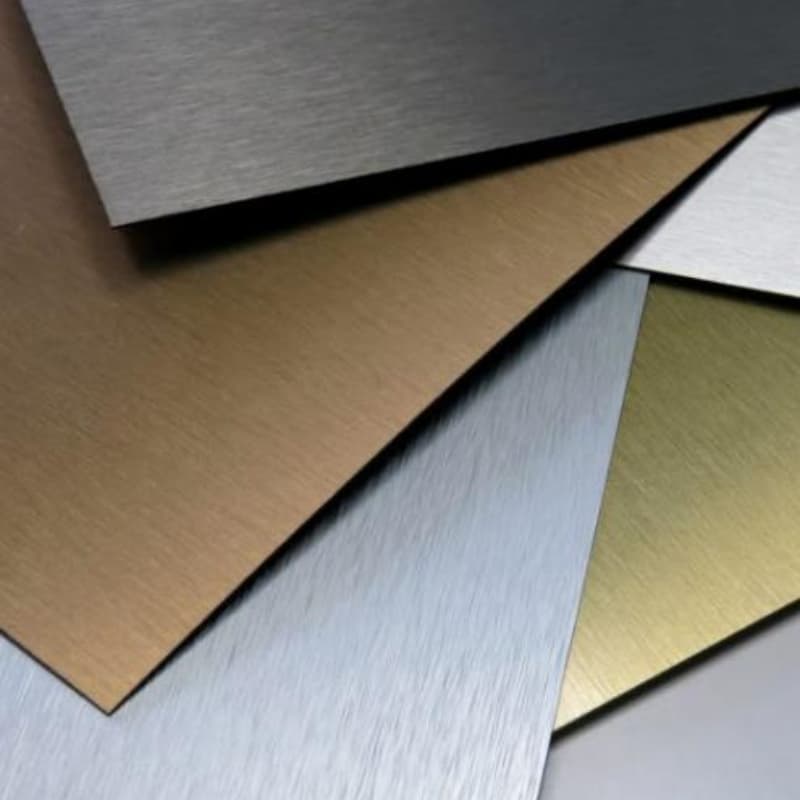

Metallic pigment powder delivers mirror-like finishes for automotive and industrial coatings through precision-engineered aluminum flakes. These organic-coated particles achieve 95% orientation (ASTM D5767) with flake thickness ≤0.2μm (ISO 13320), creating dynamic light reflection. The powder withstands 200°C curing temperatures (ASTM D2486) and maintains ΔE ≤1.0 after 3,000 hours of salt spray (ASTM B117).

Formulated for waterborne and solvent systems, our pigments reduce VOC emissions by 70% compared to conventional metallics. With 700MT monthly production, batches show ≤2% variance in flake geometry, critical for color-matching in OEM automotive lines. Surface treatments enhance corrosion resistance, achieving 1,500-hour cyclic corrosion compliance (SAE J2334).

Technical Advantages

200°C bake stability without oxidation

≤0.5% flake fracture during spraying

98% adhesion to galvanized substrates

Halogen-free and REACH compliant

Applications

Automotive exterior coatings

Appliance powder coatings

Marine anti-corrosion paints

Certifications

REACH Annex XVII Compliance

ISO 9001:2015

GMPA 6-20 Weathering Standard

Project Cases

2018: German Automotive Line

Supplied 25MT of aluminum pigment for car bodies, achieving 0.85 DOI (ASTM D5767).

2021: US Appliance Manufacturing

Developed 18MT of UV-stable pigment for refrigerators, maintaining ΔE ≤0.7 after 5-year indoor exposure.

2023: Southeast Asian Marine Coatings

Delivered 15MT of seawater-resistant pigment, passing 2,000-hour ASTM D5894 testing.

Copyright © 2024 Fineland Chem Co., Ltd /HangZhou FanCheng Chemical Co., Ltd.